STEAMATIC OF ALBUQUERQUE AND SANTA FE, NEW MEXICO

Issue

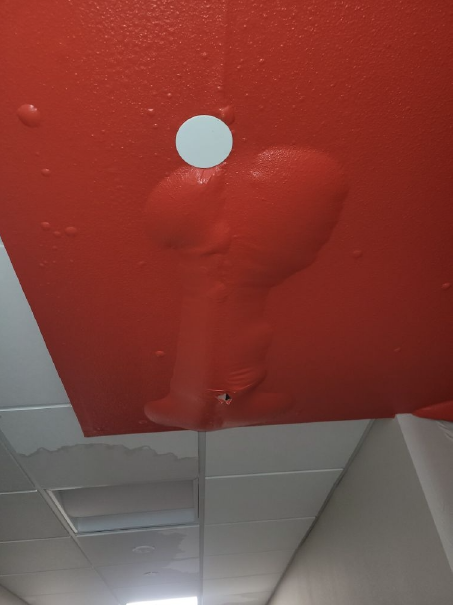

On February 14, 2021, a facility manager from a local community college contacted Steamatic of Albuquerque and Santa Fe to request emergency restoration services after a fire suppression line ruptured at one of their buildings. Water ran for a few hours before this was noticed, and water had affected Levels 1 and 2. Both floors had standing water.

Plan of Action

Steamatic crews responded afterhours on that evening for emergency extraction; an 8-person crew extracted water from 6:30 pm until 1:30 a.m. The fire suppression lines ruptured three additional times during that period, and the fire suppression company was finally called by the facility manager to stop the leak. The water was black, smelly, and had originated from the lines that had not been flushed in many months, and the Category of water loss was determined to be a Category 3.

Solution

After reviewing the project and the drying plan with the facility manager, the scope of work was authorized. Steamatic advised that drywall, insulation, ceiling tiles, fabric cubicles, and other porous structural materials affected should be removed and replaced per IICRC S500. Content, such as desks, chairs, personal items, window, electronics would need to be cleaned or disposed of per IICRC S500.

Proscess

The content was safely moved and protected. Other items, like computers, were moved to different areas per the client’s request. Demo of contaminated building materials began on 2/17/21, and the crew worked to wipe down all electronics, shelves, and tabletops. The team moved to the second floor on 2/25/21 to repeat the same process of carefully manipulating content, demo’ing affected materials, and cleaning other items in place.

Simultaneously, Steamatic construction crews were following the mitigation teams to replace insulation, hang and tape drywall, paint, and replace ceiling tiles and other. Together, the two teams completed the project in just 15 days.

Outcome

Many long hours were required to complete this project in the timeline required by the school. The facility manager needed Steamatic to do whatever it would take to return the building to safe occupancy. He said, “Do it right. Keep my kids safe in this building.” A rigorous three-shift schedule was needed by our mitigation and construction teams to complete the project by the agreed upon date, and this is exactly what Steamatic did!

Recent Comments